The manufacturing industry is changing rapidly. It’s no longer just about automation; factories are now being designed to think, learn, and improve independently. This transformation is powered by Artificial Intelligence (AI), especially Generative AI in manufacturing, which makes factories smarter, faster, and more efficient.

According to McKinsey, Generative AI could add $275–$460 billion annually to the global manufacturing and supply chain sectors. That’s a massive opportunity. AI in smart manufacturing is already helping factories predict equipment failures, accelerate production, reduce waste, and improve quality creating a more connected, flexible, and intelligent way of working.

Transitioning to this new era doesn’t happen overnight. It requires a clear strategy, the right tools, and expert guidance. This blog explores how Generative AI is transforming smart manufacturing and how Prolifics can help your business shift from traditional operations to an AI-powered future.

Benefits of Generative AI in Manufacturing:

• Accelerated product development

• Reduced material waste and costs

• Smarter, AI-driven production lines that adapt in real time

• Enhanced decision-making through real time data

• Augmented human capability without replacing workers

The Rise of Smart Manufacturing with AI

Smart manufacturing also known as Industry 4.0 integrates IoT, robotics, cloud computing, and AI to create intelligent, automated production systems.

As manufacturers face rising customer expectations, global competition, and supply chain disruptions, these technologies have become essential for speed, efficiency, and cost effectiveness.

According to Deloitte, 86% of manufacturers believe smart factory initiatives will be their top competitive driver in the next five years. Among these, Generative AI stands out especially in predictive maintenance, which helps factories anticipate failures, minimize downtime, and optimize performance.

Generative AI’s Role in Shaping the Future of Manufacturing

1. Product Design & Prototyping

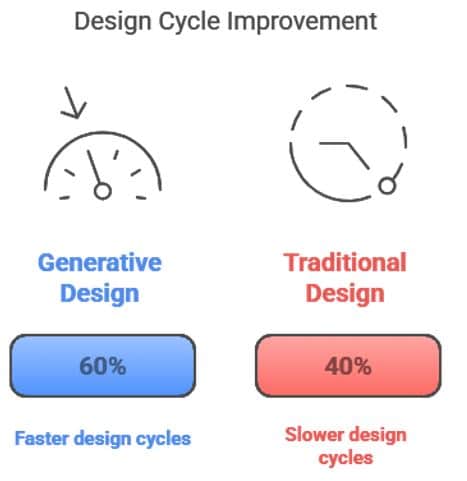

AI-powered manufacturing is revolutionizing product design and development. Generative AI can explore thousands of design options in seconds, helping engineers find the best solution that balances performance, cost, and material usage. This not only saves time but also unlocks new levels of innovation in product development.

Stats:

- Material & Time Savings: According to Autodesk, generative design can reduce material use by 40% and accelerate design cycles by up to 60%.

- Use Case: An aerospace company used Generative AI to redesign aircraft brackets. The result? A part that was 30% lighter but still met all strength and safety requirements.

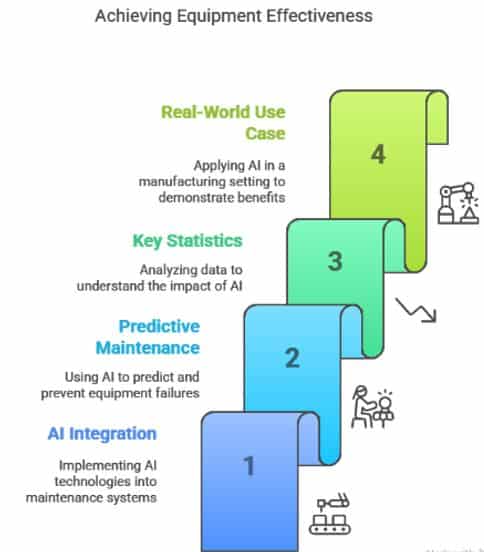

2. AI for Preventing Breakdowns and Improving Equipment Efficiency

AI-powered predictive maintenance tools analyze data from factory equipment to predict potential failures before they happen. This is a key component of manufacturing digital transformation, helping to reduce downtime, minimize repair costs, and extend the lifespan of machinery.

Stats:

- Reduction in Equipment Breakdowns

According to a study by Deloitte, companies that adopt predictive maintenance can reduce equipment breakdowns by up to 70% and lower maintenance costs by 25%.

- Improvement in Equipment Effectiveness

A manufacturer implementing AI-driven predictive maintenance reported a 25% improvement in Overall Equipment Effectiveness (OEE), directly contributing to reduced unscheduled downtime. - Decrease in Unplanned Downtime

Industry reports indicate that AI-powered predictive maintenance can reduce unplanned downtime by up to 50%, lower maintenance costs by 10–40%, and increase overall productivity by 20–30%. - Use Case: A global automotive manufacturer used predictive AI to monitor machine health, preventing unexpected breakdowns and saving millions in lost production.

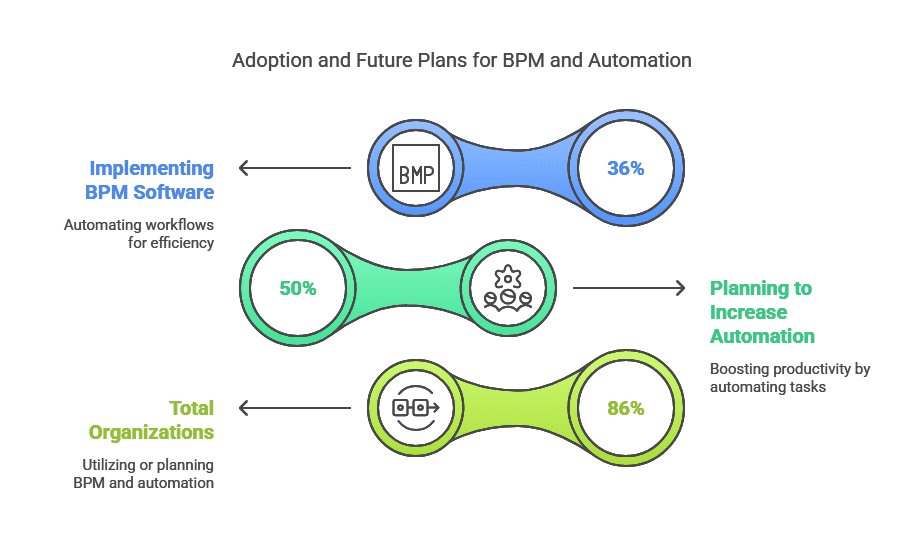

3. Production Planning & Workflow Automation

Generative AI in manufacturing is transforming how production is planned and executed. Gen AI tools generate optimized production schedules based on variables like demand forecasts, raw material availability, and labor constraints.

Stats:

Workflow Automation Statistics

36% of organizations are already implementing Business Process Management (BPM) software to automate workflows, enhancing efficiency and reducing errors.

50% of business leaders plan to increase the automation of repetitive tasks within their organizations, aiming to boost productivity and reduce operational costs.

Use Case: Gen AI can simulate and adjust workflows in real-time, helping factories stay lean and agile.

4. Quality Control & Defect Detection

Smart factories powered by artificial intelligence (AI) are transforming the manufacturing landscape. By utilizing Generative AI, manufacturers can create synthetic data sets that train computer vision systems to detect defects, even in rare and complex scenarios.

Stats:

- Defect Detection Accuracy

AI systems can detect defects with an accuracy rate exceeding 90%, compared to 70-80% accuracy with manual inspections. - Cost Reduction

A McKinsey study estimates that AI-driven quality control can reduce manufacturing costs by up to 20%, translating to significant savings globally. - Market Growth

The global defect detection market is projected to grow from USD 3.5 billion in 2021 to USD 5.0 billion by 2026, at a CAGR of 7.5%. - Use Case: Semiconductor companies leverage AI-generated defect images to build more robust inspection models, reducing the need for thousands of real-world examples.

5. AI for Optimizing Supply Chains and Managing Risks

AI-powered manufacturing is transforming how supply chains are managed. Gen AI can model various supply chain disruptions and suggest adaptive logistics strategies, all while supporting AI-enhanced quality control for improved product consistency.

Stats:

- According to a report by Boston Consulting Group (BCG), companies utilizing AI-driven supply chain simulations have achieved up to a 30% improvement inforecast accuracy and reductions of 50% to 80% in delays and downtime. These advancements contribute to improving on-time delivery rates and overall supply chain efficiency.

- Use Case: During COVID-19, several manufacturers used AI simulations to reroute shipments and maintain service levels, while also ensuring enhanced quality control throughout the process.

6. Training & Workforce Augmentation

The role of generative AI in factory automation is rapidly expanding, as AI-generated simulations and digital twins enable immersive training environments and interactive manuals. This technology enhances training, reduces errors, and streamlines maintenance processes.

Stats:

- Learning Efficiency: According to Gartner, adaptive learning powered by AI can reduce training time by 30% while increasing retention by 25%.

- Knowledge Retention: A study by FIO Labs reported a 67% improvement in knowledge retention when utilizing AI-driven smart learning systems.

- Use Case: AR glasses powered by Generative AI offer real-time guidance during machine repairs, cutting human error significantly and improving efficiency.

Emerging AI Innovations in Smart Manufacturing:

As smart factories evolve, new forms of Artificial Intelligence are pushing the boundaries of what’s possible. Below are some of the latest breakthroughs redefining manufacturing intelligence:

Agentic AI in Manufacturing:

Agentic AI is revolutionizing manufacturing by introducing autonomous systems capable of decision-making, predictive maintenance, quality control, and supply chain optimization.

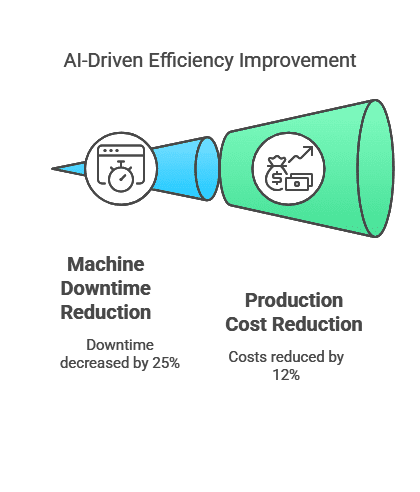

Stats: An automotive manufacturer collaborated with Infiniti Research to implement an AI-powered predictive maintenance solution. The result was a 25% decrease in machine downtime and a 12% reduction in production costs.

Digital Twins in Manufacturing: Predictive Maintenance

Digital twins, virtual replicas of physical assets, enable real-time monitoring and predictive maintenance, leading to significant operational improvements.

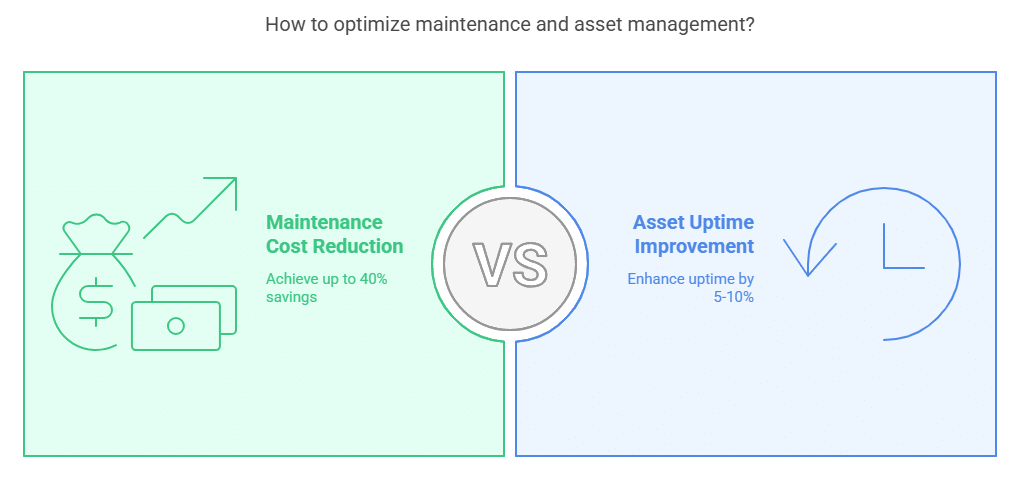

Stats: A staggering statistic from McKinsey shows us this is no flash in the pan; using digital twins can slash maintenance costs by up to 40% while boosting asset uptime between 5–10%.

AI Vision in Manufacturing: Defect Detection in Real-Time

AI-powered visual inspection systems have revolutionized manufacturing by enabling rapid, automated defect detection across production lines.

These systems can analyze thousands of items per minute, ensuring high-quality standards and minimizing the risk of defective products reaching the market.

Edge AI in Smart Manufacturing

Edge AI enables immediate analysis of sensor data from machines and production lines, allowing for swift adjustments and minimizing delays.

By analyzing equipment data locally, edge AI can predict failures before they occur, reducing downtime and maintenance costs.

Real-World Success Stories: How Generative AI is Transforming Manufacturing

Generative AI is driving a digital revolution in manufacturing from product design optimization to intelligent supply chain management. Leading manufacturers are using it to enhance innovation, efficiency, and resilience.

The Road Ahead: AI-Powered Autonomous Factories

Generative AI isn’t just improving manufacturing it’s redefining it. From design to delivery, AI transforms traditional factories into agile, intelligent ecosystems that learn and optimize continuously.

Companies adopting Generative AI today are building tomorrow’s competitive edge through smarter decisions, faster innovation, and sustainable growth.

Inference: Shaping the Future of Smart Manufacturing

AI-powered smart factories are transforming how manufacturing operates. Generative and Industrial AI solutions help organizations become more agile, intelligent, and resilient.

Prolifics plays a key role in guiding businesses through this transformation, using cutting-edge AI to deliver:

- Improved operational efficiency

- Predictive insights

- Sustainable growth

Contact us today to learn how Prolifics can accelerate your AI-driven manufacturing journey.