Modern manufacturing is changing fast. Factories are no longer limited by human work shifts or manual checks. Instead, they are moving toward lights-on manufacturing, where production runs all the time, without stopping, and makes smart decisions on its own. The key to this change is agentic AI in manufacturing, a new type of artificial intelligence that can think and act independently.

In this blog, we will explain how continuous autonomous operations work, why they are important, and how agentic AI in manufacturing is transforming the future of 24/7 smart manufacturing and intelligent industrial environments.

What Are Lights-On Operations in Modern Manufacturing?

Lights-on operations refer to manufacturing environments that function 24/7 with minimal or no human intervention, even during nights, weekends, or holidays. The term originates from the idea that factories no longer need constant human presence or even physical lighting to operate, a core principle of lights-on manufacturing.

In a lights-on factory, machines check their own health, and production lines adjust automatically to demand. Quality is monitored in real time, and issues are fixed or escalated without human help, enabling autonomous manufacturing systems to operate reliably at scale.

• Machines self-monitor performance and health

• Production lines automatically adjust to demand

• Quality checks happen in real time using vision systems

• Exceptions are handled autonomously or escalated digitally

This approach is essential for AI-driven smart factories, where speed, accuracy, and reliability make all the difference. Continuous autonomous operations allow manufacturers to meet global demand, keep processes consistent, and handle disruptions instantly without waiting for human intervention, strengthening intelligent manufacturing operations across facilities.

Role of Agentic AI in Achieving 24/7 Efficiency

Agentic AI in manufacturing enables factories to run continuously without human involvement. Through real-time decision-making, adaptive responses, and seamless process coordination, agentic AI delivers the speed, precision, and resilience required for uninterrupted 24/7 smart manufacturing and large-scale autonomous manufacturing systems.

What Makes Agentic AI Different?

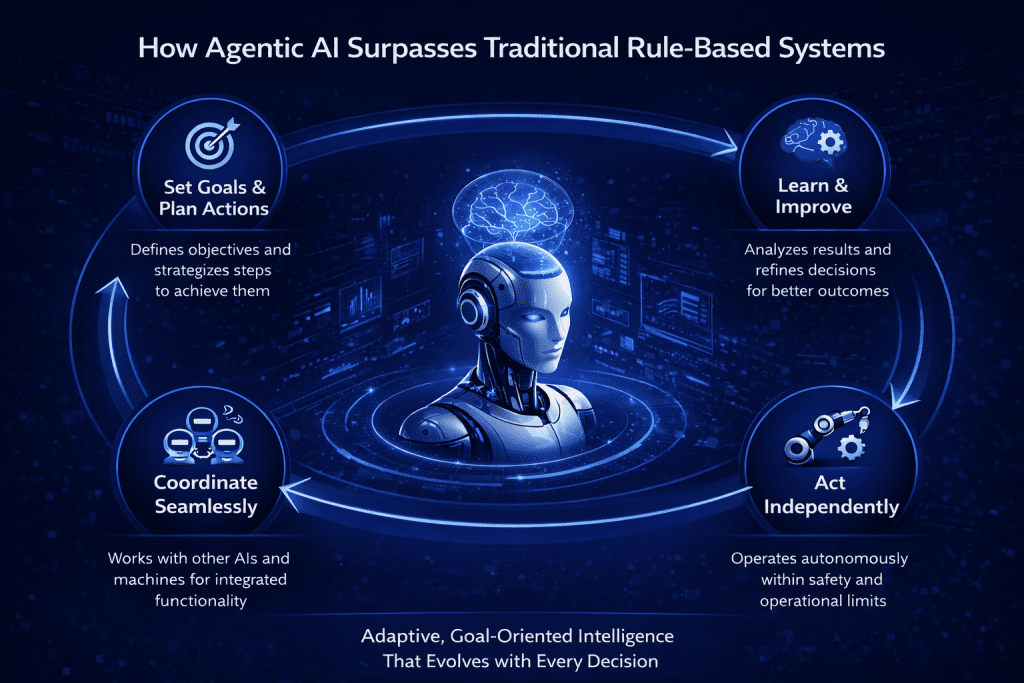

Agentic AI surpasses traditional rule-based systems by introducing adaptive, goal-oriented intelligence that evolves with every decision. It can be:

• Set goals and plan actions to achieve them

• Learn from outcomes and improve decisions over time

• Coordinate with other AI agents and machines for seamless operations

• Act independently within defined safety and operational constraints

This intelligence layer is foundational for intelligent manufacturing operations that require minimal human oversight while maintaining high performance.

Key Benefits from Predictive Maintenance to Zero Downtime

Predictive maintenance allows manufacturers to address issues before equipment failure occurs, minimizing unplanned downtime. This supports smoother operations, improved efficiency, and more reliable production in AI-driven smart factories.

Predictive Maintenance

Agentic AI for predictive maintenance in factories analyzes sensor data, vibration patterns, and historical failures to predict breakdowns before they occur. Maintenance becomes proactive rather than reactive, significantly extending equipment life.

Reduced Downtime

By anticipating failures and optimizing schedules, factories move closer to near-zero unplanned downtime, a major cost saver in high-volume lights-on manufacturing environments.

Optimized Workflows

AI agents dynamically balance workloads across machines, adjust production sequences, and eliminate bottlenecks without manual planning, enabling self-optimizing manufacturing systems.

Cost and Energy Efficiency

Continuous optimization reduces waste, minimizes scrap, and lowers energy consumption by running machines only when needed and at optimal settings, strengthening 24/7 autonomous manufacturing operations with AI.

Consistent Quality

AI-driven inspection systems detect defects in real time, ensuring uniform quality even at high production speeds within autonomous manufacturing systems.

Challenges and Considerations for Implementation

Despite its promise, implementing lights-on operations powered by agentic AI in manufacturing is not without challenges. Organizations must address issues such as integrating data from legacy systems and ensuring strong cybersecurity measures. In addition, workforce upskilling and clear governance frameworks are essential to build trust in autonomous decision-making systems.

Data Integration

Factories often operate with fragmented legacy systems. Integrating PLCs, MES, ERP, and IOT platforms into a unified data fabric is complex but essential for intelligent manufacturing operations.

Cybersecurity Risks

Autonomous, connected systems expand the attack surface. Strong cybersecurity architectures, real-time monitoring, and zero-trust models are mandatory for AI-driven smart factories.

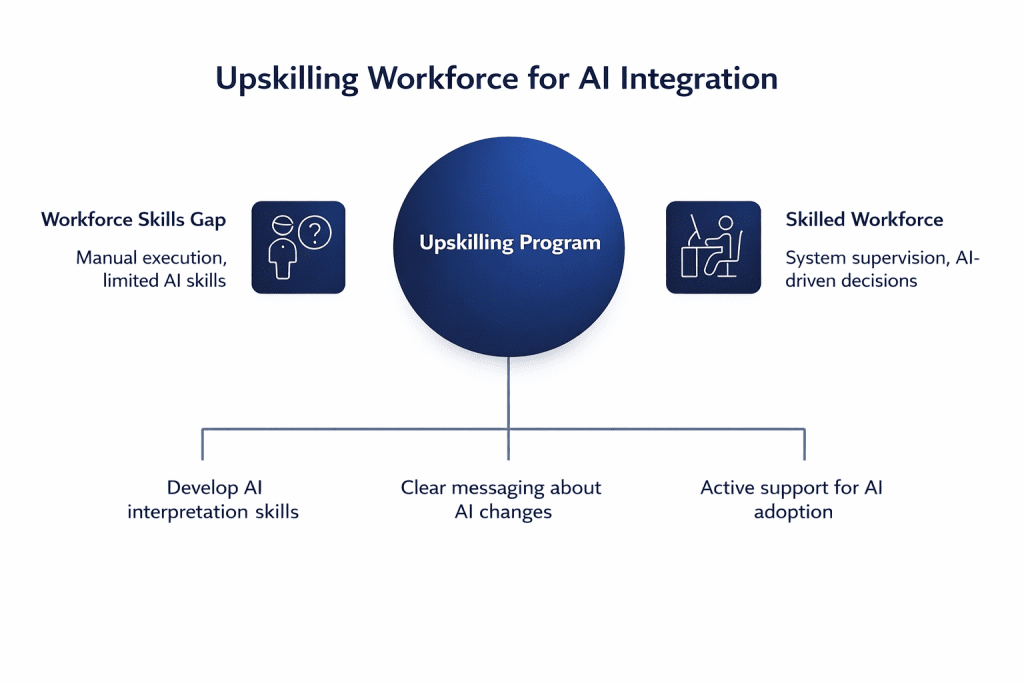

Workforce Adaptation

Lights-on manufacturing does not eliminate jobs; it changes them. Workers must transition from manual control to roles focused on supervision, AI training, system design, and exception handling.

Governance and Trust

Giving AI decision-making authority requires clear boundaries, explainability, and auditability to ensure safety and compliance.

Workforce Skills and Change Management

As factories adopt lights-on manufacturing and agentic AI in manufacturing, the role of the workforce shifts from manual execution to system supervision and decision support. Employees must be upskilled to work alongside intelligent systems, interpret AI-driven insights, and manage exceptions.

Effective change management, including training, clear communication, and leadership support, is essential to ensure smooth adoption and long-term success.

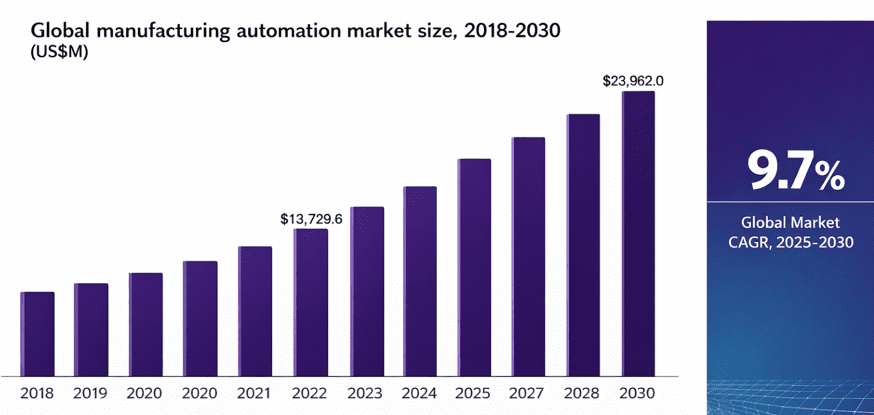

Scaling Agentic AI Across Global Manufacturing

As manufacturers scale globally, agentic AI in manufacturing will evolve from isolated deployments to networked intelligence across plants, regions, and supply chains.

Key trends shaping the future include:

• Digital twins that simulate entire factories in real time

• Multi-agent systems coordinating across production, logistics, and procurement

• Self-optimizing supply chains that adapt instantly to demand shocks

• Deeper integration with Industry 4.0 standards and, eventually, Industry 5.0’s human-centric focus

In the coming years, competitive advantage will no longer come from automation alone but from autonomous intelligence at scale within 24/7 smart manufacturing ecosystems.

Conclusion

Lights-on operations powered by agentic AI in manufacturing represent a significant shift in modern manufacturing, enabling continuous, intelligent, and reliable production. By combining predictive maintenance, autonomous decision-making, and optimized workflows, manufacturers can reduce downtime, improve efficiency, and remain competitive in a rapidly evolving industrial landscape.

Learn how cloud-based ERP modernization supports scalable, intelligent manufacturing by exploring this SAP S/4HANA Cloud modernization case study.

While challenges around technology, security, and workforce adaptation remain, organizations that invest thoughtfully in these areas will be best positioned to lead the next phase of intelligent manufacturing operations.