The promise of industrial automation has always been to improve safety, quality, and productivity. Yet many manufacturers still face labor shortages, skill gaps, and safety concerns that automation alone hasn’t solved. That’s where humanoid factory workers come in. Unlike traditional industrial robotics, rigid, fixed machines designed for repetitive single tasks, humanoid robots are built to move, act, and even “think” like people.

According to Fortune Business Insights, the global Humanoid Robots in Manufacturing and robotics market reached $43.8 billion in 2023 and will nearly double by 2032. Even more striking, Grand View Research reports the humanoid robot market could grow at a staggering 63.5% CAGR through 2030. These figures underline a simple truth: humanoids are not science fiction. They are the next chapter of smart manufacturing.

Rather than replacing human workers, human-robot collaboration (HRC) is the goal. AI humanoid robots in manufacturing are designed to complement people by taking on repetitive or dangerous tasks while employees focus on higher-value, creative work. Gartner and Forrester both highlight how this balance is key to future productivity and resilience in manufacturing.

Where Humanoids Fit in Industry 4.0 and Beyond

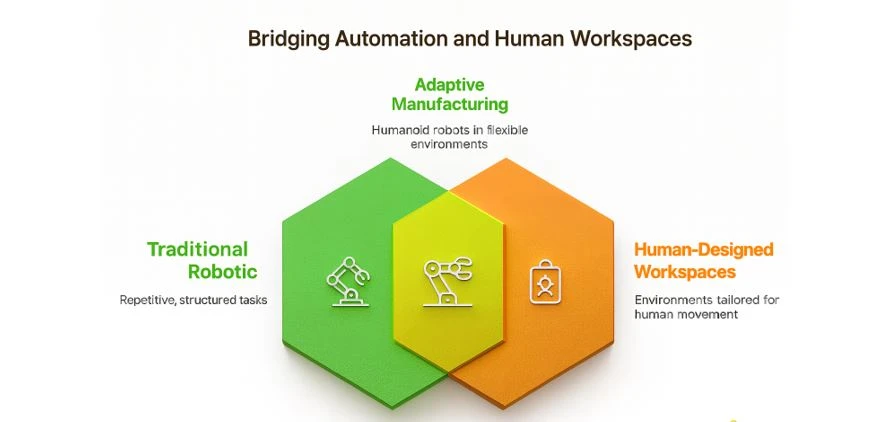

Smart factory technology is powered by interconnected systems: IoT sensors, MES/ERP platforms, RPA on the business side, and AI analytics that guide decision-making. Until now, automation has struggled with tasks designed for humans, climbing stairs, handling delicate parts, or working in tight spaces.

Humanoid Robots at Work extend Adaptive Manufacturing into these areas. They can connect to existing factory systems, report production data in real time, identify bottlenecks, and even suggest improvements. This allows businesses to bridge the last mile between traditional robotic automation and human-designed workspaces. For companies exploring how to implement robots in manufacturing, humanoids represent the missing link between automation and human efficiency.

Technology Building Blocks Driving Transformation

AI & Machine Learning

Generative AI in industrial robotics enables robots to learn new tasks quickly, adapt to changing environments, and improve efficiency. Research shows examples of humanoid robots in manufacturing demonstrate that they can now learn new assembly tasks with 85% fewer demonstrations than older models.

Sensing & Vision

Equipped with 3D vision and force feedback, humanoids improve quality inspections, handle delicate parts, and operate safely in human-robot collaboration (HRC) environments.

Mobility & Dexterity

Modern designs allow robots to walk on uneven surfaces, climb ladders, use human tools, and complete complex tasks once thought impossible for machines. These advancements highlight the benefits of humanoid factory workers—not only improving safety but also handling tasks beyond traditional automation.

Business Value & ROI: Day 1 vs. Day 365

How humanoid robots improve factory efficiency becomes clear from day one.

- Day 1: Reduced worker exposure to hazardous tasks, streamlined uptime, and faster repetitive processes.

- Day 365: Continuous operation, 30–50% productivity gains, fewer defects, and shorter ROI cycles.

According to McKinsey, ROI periods for humanoid deployment have dropped from 5.3 years in 2019 to just 2.8 years in 2023. Oxford Economics adds that companies using AI-powered humanoid robots report labor cost reductions of 22–28% within the first year.

Sample KPI Tracking Framework

| KPI | Baseline | After 1 Year |

| OEE (Overall Equipment Effectiveness) | 65% | 80%+ |

| FPY (First Pass Yield) | 90% | 95%+ |

| Scrap Rate | 5% | 2% |

| Injury Rate | Industry average | 35–50% reduction |

| Payback Period | 3–5 years | 18–24 months |

Safety & Compliance Enhancements

Humanoid Robots in Manufacturing directly improve workplace safety by handling heavy lifting, repetitive motions, and hazardous material exposure. OSHA data shows that factories deploying humanoid robotics cut exposure-related incidents by more than 50%. The U.S. Bureau of Labor Statistics also found that automation-heavy plants saw injury rates drop by 35%.

For manufacturers, this not only protects workers but also supports compliance with stringent safety and labor regulations. It also showcases the impact of AI on manufacturing workforce safety and sustainability.

Implementation Roadmap

- Assessment & Use-Case Prioritization – Identify tasks suited for humanoids: repetitive, hazardous, or precision-based.

- Pilot Design – Establish KPIs and capture performance data.

- Systems Integration – Connect robots with MES/ERP/PLC systems, ensure cybersecurity and data management.

- Change Management & Training – Upskill workers, define roles in human-robot collaboration (HRC).

- Scale-Up Strategy – Move from cell pilots to line and plant-wide deployments.

For companies considering how to implement robots in manufacturing, this roadmap provides a practical framework.

Potential Risks and Solutions

- Upfront Costs: While prices have come down to the $100k–$150k range per unit, many small and mid-sized businesses still see this as a significant investment. To reduce financial barriers, options such as leasing models, subscription-based Robot-as-a-Service (RaaS), and phased deployment can spread out costs and make adoption more feasible.

- Integration with Legacy Systems: Older IT and operational systems can create roadblocks when connecting new automation technologies. Leveraging middleware platforms, APIs, and standardized reference architectures helps bridge compatibility gaps, ensuring smooth connectivity without costly overhauls.

- Programming Complexity: Traditional robot programming requires specialized expertise, which can limit scalability. Emerging solutions like low-code or no-code task teaching, paired with Generative AI in industrial robotics, reduce reliance on scarce technical talent and speed up deployment.

- Workforce Acceptance: Employees may resist robotics adoption due to concerns about job security or role changes. Organizations can address this by clearly communicating the purpose of automation, emphasizing how it enhances rather than replaces human work, investing in upskilling opportunities, and redefining roles to highlight collaboration between people and machines.

These reflect some of the challenges of deploying humanoid robots in real-world environments.

How Prolifics Can Help

At Prolifics, we partner with manufacturers to navigate every stage of their AI manufacturing automation journey, ensuring technology investments translate into measurable business value. Our approach spans strategy, integration, innovation, and workforce readiness:

- Strategic Assessments: We begin with in-depth evaluations of operations, supply chains, and production environments to identify the areas where humanoid robotics and warehouse automation robotics deliver the highest ROI. This ensures automation efforts are targeted, impactful, and aligned to business priorities.

- Systems Integration: Manufacturing success depends on seamless connectivity. We integrate robotics solutions across MES (Manufacturing Execution Systems), ERP, IoT, and cloud platforms, building a unified ecosystem that eliminates silos and enables real-time visibility and control across operations.

- AI and Data Solutions: Beyond robotics, our AI capabilities amplify manufacturing efficiency. We deploy advanced analytics for demand forecasting, apply Generative AI in industrial robotics to speed programming and reconfiguration, and use digital twins to simulate and predict asset performance, helping reduce downtime and improve throughput.

- Change Management Programs: Technology is only part of the journey. We design programs that prepare workers for the future of manufacturing jobs with AI, focusing on clear communication, upskilling, and redefining roles to encourage collaboration between humans and intelligent machines.

By blending deep industry expertise with proven technology accelerators, Prolifics enables manufacturers to accelerate adoption, reduce costs, and achieve sustainable ROI from humanoid robotics and automation, while building a foundation for long-term competitiveness and innovation.

Key Takeaways: Embracing the Humanoid Future

The rise of humanoid robots in manufacturing 2026 and beyond is reshaping industries into safer, smarter, and more productive environments. By embracing AI-powered humanoid robots as partners in the smart factory landscape, businesses can achieve resilience, efficiency, and innovation that outpace competitors.

As leaders consider the Future of manufacturing jobs, they must also explore Industry 4.0 vs Industry 5.0 robotic strategies to ensure long-term adaptability. The future isn’t about humans or robots; it’s about both working side by side.